Process of Solar Dehydration

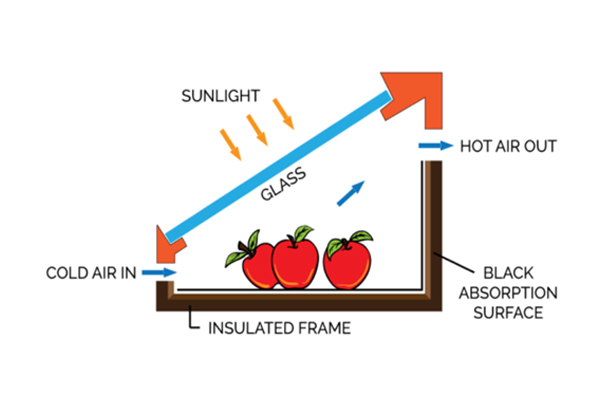

Solar dryers utilise solar energy to dry substances by converting light into heat and effectively trapping it.

- Energy change: The first step is to trap any light which falls on it and convert it into heat. The presence of any black surface on the dryer is likely to push the effectiveness of the energy conversion substantially

- The heat trap: The next step is to trap the heat so that it could be put to use later. This is why the air is isolated inside the dryer and separated from the one outside it. A plastic bag or a glass cover is used to make sure that light when entered inside is unable to move outside. Due to this mechanism, regardless of the outer weather and temperature, specific temperatures can be attained with the solar dryer

- Transfer of heat: The final step is to apply the convection form of the heated air over the food or the substance which is to be dried by application of this trapped heat.

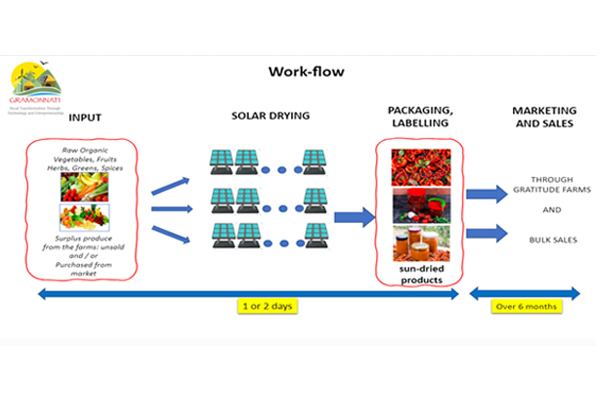

Step-by-Step Solar Drying Process for Quality Vegetables

- Grading : Begin by carefully sorting and grading the vegetables to ensure the quality of produce

- Warm Water Treatment : Treat the chosen vegetables with warm water to remove any impurities and enhance the overall drying efficiency.

- Cutting and Drying : After the warm water treatment, cut the vegetables into appropriate pieces, optimising their drying time. Then, place the prepared pieces inside the solar dryer.

- Quality Check : Once the vegetables are thoroughly dried, perform a stringent quality check to ensure they meet the desired standards of texture, colour, and taste.

- Packing and Logistics : Once the quality check is completed, Vacuum pack the solar-dried vegetables carefully. The packed products are then ready to be sent for storage or distribution through logistics.